Air Cooled Heat Exchangers: Nature's Helping Hand in Heat Removal

Introduction

In the realm of industrial processes, efficient heat removal is crucial for maintaining optimal performance and ensuring safe operations. One ingenious solution that harnesses the power of nature is air cooled heat exchangers. These remarkable devices leverage the cooling properties of air to dissipate heat generated during various manufacturing and production processes.

What are Air Cooled Heat Exchangers?

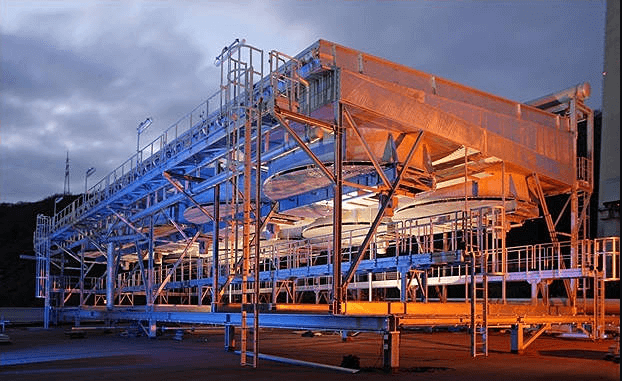

Air cooled heat exchangers are specialized equipment designed to transfer heat from a hot fluid or gas to the surrounding air. Unlike their water-cooled counterparts, these heat exchangers rely solely on air as the cooling medium, eliminating the need for water or other liquid coolants.

What is the primary function of air cooled heat exchangers?

The primary function of air cooled heat exchangers is to transfer heat from a hot fluid or gas to the surrounding air, facilitating efficient cooling and heat removal.

The Principles Behind Air Cooling

Air cooled heat exchangers operate on the principles of convection and radiation. Hot fluids or gases flowing through the heat exchanger tubes release heat through convection to the tube walls. This heat is then dissipated to the surrounding air through a combination of conduction, convection, and radiation.

What are the main principles involved in the operation of air cooled heat exchangers?

Air cooled heat exchangers operate based on the principles of convection and radiation. Convection transfers heat from the hot fluid or gas to the tube walls, while conduction, convection, and radiation dissipate the heat to the surrounding air.

Advantages of Air Cooled Heat Exchangers

Air cooled heat exchangers offer several advantages over their water-cooled counterparts, making them a preferred choice in many industries.

1. Environmental Friendliness

By eliminating the need for water or other liquid coolants, air cooled heat exchangers significantly reduce the environmental impact associated with coolant usage, treatment, and disposal.

2. Low Maintenance

With no liquid coolants involved, these heat exchangers are less prone to corrosion, scaling, and fouling, resulting in reduced maintenance requirements and lower operational costs.

What is one of the main advantages of air cooled heat exchangers over water-cooled systems?

One of the main advantages of air cooled heat exchangers is their environmental friendliness, as they eliminate the need for water or other liquid coolants, reducing the environmental impact associated with coolant usage, treatment, and disposal.

Applications of Air Cooled Heat Exchangers

Air cooled heat exchangers find applications in a wide range of industries, including:

1. Power Generation

In power plants, air cooled heat exchangers are used to cool steam condensers, transformers, and other auxiliary equipment, ensuring efficient energy production.

2. Petrochemical and Chemical Processing

These heat exchangers play a crucial role in cooling various process fluids and gases in refineries, petrochemical plants, and chemical processing facilities.

In which industry are air cooled heat exchangers commonly used for cooling steam condensers and transformers?

Air cooled heat exchangers are commonly used in the power generation industry for cooling steam condensers, transformers, and other auxiliary equipment.

Design Considerations for Air Cooled Heat Exchangers

To ensure optimal performance and efficiency, several factors must be considered when designing air cooled heat exchangers:

1. Fin Design

The fin design plays a critical role in enhancing heat transfer by increasing the surface area exposed to the air. Various fin configurations, such as plate fins, tube-fin, and louvered fins, are employed to optimize heat dissipation.

2. Air Flow Management

Proper air flow management is essential for efficient heat transfer. This involves considering factors like fan placement, air flow direction, and wind effects to ensure optimal air circulation around the heat exchanger tubes.

What is the purpose of fin design in air cooled heat exchangers?

The fin design in air cooled heat exchangers plays a critical role in enhancing heat transfer by increasing the surface area exposed to the air, allowing for more efficient heat dissipation.

Factors Affecting Performance

While air cooled heat exchangers are highly efficient, their performance can be influenced by several environmental and operational factors:

1. Ambient Air Temperature

Higher ambient air temperatures can reduce the heat transfer efficiency, potentially leading to higher operating temperatures and decreased performance.

2. Wind Conditions

Wind can significantly impact the heat transfer rate by influencing the air flow patterns around the heat exchanger tubes.

How can wind conditions affect the performance of air cooled heat exchangers?

Wind conditions can significantly impact the performance of air cooled heat exchangers by influencing the air flow patterns around the heat exchanger tubes, affecting the heat transfer rate.

Maintenance and Monitoring

To ensure optimal performance and longevity, regular maintenance and monitoring of air cooled heat exchangers are essential. This includes:

1. Cleaning

Periodic cleaning of the heat exchanger tubes and fins is crucial to remove accumulated dust, debris, and other contaminants that can impede heat transfer.

2. Monitoring and Inspection

Regular monitoring and inspection of the heat exchanger components, including fans, motors, and structural integrity, can help identify potential issues and prevent failures.

Why is regular cleaning important for air cooled heat exchangers?

Regular cleaning of air cooled heat exchangers is important to remove accumulated dust, debris, and other contaminants from the heat exchanger tubes and fins, which can impede heat transfer and reduce efficiency if left unchecked.

Conclusion

Air cooled heat exchanger are a remarkable example of how nature can lend a helping hand in addressing industrial challenges. By harnessing the cooling power of air, these innovative systems provide an efficient and environmentally friendly solution for heat removal across various industries. As technology continues to advance, air cooled heat exchangers will undoubtedly play an increasingly vital role in ensuring sustainable and efficient operations, while minimizing environmental impact.